Testing electric motors

In an electric car, the electric motor is the beating heart that converts the energy from the battery into direct, silent propulsion.

5.1 Overview of different electric motors

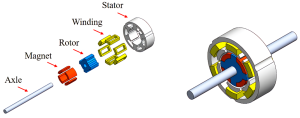

The most commonly used configuration in modern passenger EVs is the permanent magnet synchronous motor (PMSM). In this machine, the rotor is equipped with neodymium magnets that generate a powerful and constant field; the stator swings around this field, generating alternating current waves that cause the rotor to run synchronously. The result is high efficiency – especially at low to medium speeds – and a compact design. Almost all major car brands – including Tesla, Volkswagen, Hyundai, BMW and Volvo – use PMSMs as their main traction motor. Thanks to optimised windings, advanced cooling and efficient power electronics, this motor technology remains the standard in modern EVs.

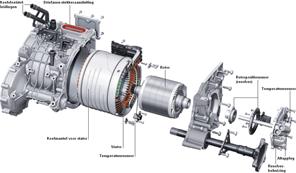

Synchronous motor Porsche Taycan

A second, equally robust but more material-friendly option is the asynchronous or induction motor. In this case, the magnetic field in the rotor is created not by magnets but by induction – the rotor is in fact a “short-circuited cage” made of aluminium or copper. Because no rare earth metals are required, material costs remain more manageable and temperature resistance is greater. However, the efficiency at partial load is generally slightly lower than with a PMSM. The induction motor, best known from Tesla, remains popular in applications where robustness and thermal resistance are important. Because they do not use permanent magnets, induction motors are also attractive to OEMs who want to be less dependent on rare earth metals. At Tesla, this motor is still often used on one of the axles, for example in AWD configurations, where it can handle prolonged peak power well.

Although less frequently used and not used in commercial designs, the switched reluctance motor is gaining ground, especially where simplicity and low cost are paramount. This motor has a very simple rotor without magnets or windings; the alternating stator field always seeks the path of least magnetic resistance and “pulls” the rotor along step by step. The absence of copper in the rotor makes it light and heat-resistant, but the pulsating forces cause extra vibrations and require acoustic design work.

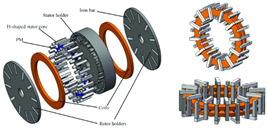

At the other end of the spectrum are the recently popularised axial flux motors. Instead of a cylindrical radial structure, the rotor and stator are arranged as discs facing each other, so that the magnetic flux runs mainly axially. This results in an exceptionally high power/torque density. This is ideal for sports cars or compact in-wheel drives – but places high demands on production precision and cooling. Car manufacturers that use these axial flux motors in a hybrid combination with a high-performance combustion engine include Mercedes AMG, Ferrari, Lamborghini and McLaren.

Lamborghini by Yasa Axial Fluc Motor

All of the motors mentioned are controlled by a traction converter that converts the direct current from the battery, pulse-width modulated, into an alternating current pattern with variable frequency and amplitude. By changing these parameters in real time, the control electronics can regulate the motor speed and torque with extreme precision. Interestingly, the motor can also function as a generator: during deceleration or downhill driving, the inverter brakes the axle, causing the mechanical energy to flow back to the battery as electrical current – a process known as regenerative braking.

5.2 Testing electric motors

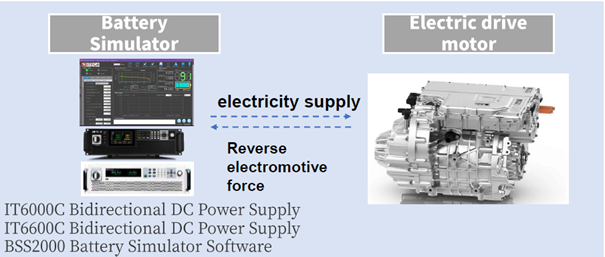

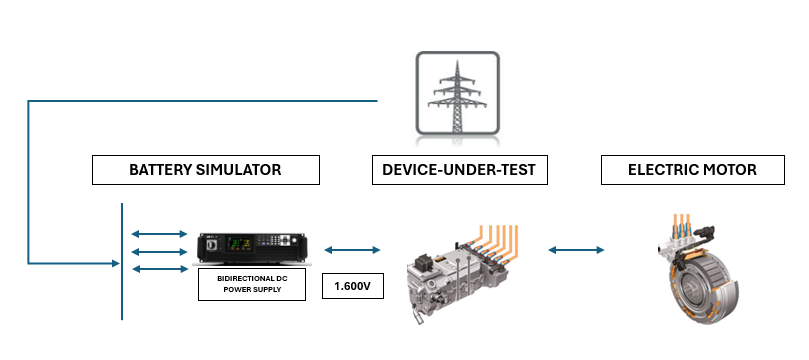

To test these motors, we can again use battery simulation power supplies (bidirectional DC power supplies) with high voltage and high power.